IT asset disposition (ITAD) focuses on reusing, repairing, repurposing, or recycling unwanted or broken IT equipment. It covers items like your printer, laptop, smartphone, tablet, desktop, scanner, etc. E-waste may seem like a hassle to get rid of, but an ITAD provider is able to recover rare metals from many items. Instead of sending old electronics to a landfill, they’re evaluated and recycled in a way that recovers as many metals as possible.

Stop and consider the damage a single iron ore mine can create. California’s Iron Mountain opened in 1896. At the time, people weren’t thinking of the environmental damage. In 1902, dead fish in the Sacramento River alerted people to the damage. Vegetation as far as 8.9 miles away was destroyed by the resulting air pollution. The acidic water from the mines and contaminated sediment entered Spring Creek and harmed fish and other creatures living downstream. The damage continued until 1990 when the EPA stepped in and started clean-up.

Instead of mining raw materials, ITAD enables companies to recycle a variety of metals for reuse. Mining operations decrease, jobs are created through recycling, and the environmental damage decreases. Here’s how the entire process works and the benefits gained from electronics recycling.

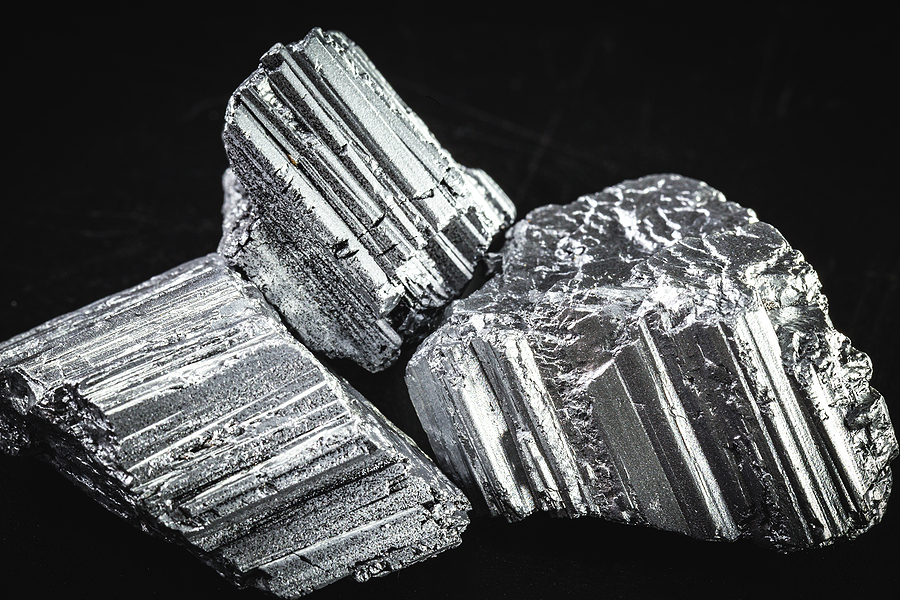

Understand What Rare Metals Are and How They’re Used

Rare earth elements (REEs) comprise 17 soft heavy metals found in many of today’s electronics. These are the 17 rare metals and their common uses.

- Cerium – Used to stabilize electrodes.

- Dysprosium – Used in magnets and magnetic data storage devices.

- Erbium – Used as an alloy that helps soften metals to make them easier to work with.

- Europium – Used to make superconducting alloys.

- Gadolinium – Used in MRI equipment and added to alloys to improve high-temperature resistance.

- Holmium – Used in MRI equipment, UV filters, and memory storage.

- Lanthanum – Used in nickel-metal hydride (NiMH) batteries found in many portable devices.

- Lutetium – Used in memory devices, LED bulbs, and diagnostic imaging equipment.

- Neodymium – Used in audio equipment, MRIs, and magnets found in hard disk drives, laptops, smartphones, and other electronics.

- Praseodymium – Used as an alloy to strengthen metal in components like electric motors.

- Promethium – Used as magnets in EVs and wind turbines and atomic batteries found in radios, pacemakers, etc.

- Samarium – Used in magnets found in small motors, headphones, and electronic devices.

- Scandium – Used in aluminum-based alloys and lighting technologies.

- Terbium – Used in TV screens, laser devices, fluorescent lights, and computer monitors.

- Thulium – Used in medical lasers, magnets in microwaves, and portable X-rays.

- Ytterbium – Used to strengthen stainless steel, also goes into atomic clocks, lasers, and solar panels.

- Yttrium – Used in LED displays, lasers, and to strengthen aluminum and magnesium.

China, the U.S., and Australia were the three leading countries producing REEs in 1993. By 2008, China was leading the field and produced more than 90%. Until 2011, China produced 97% of the REEs used in electronics. At that point, the Government of China began to limit how many REEs were produced and exported to other countries.

In the U.S., Alaska’s Bokan Mountain is one area where some rare metals can be mined. Mountain Pass in California was another option, but the mine filed for bankruptcy in 2015. It was eventually sold in 2017 and resumed mining in 2018.

The Importance of Recovering These Rare Minerals

Mining isn’t a problematic industry. In the 1980s, Unocal mined the Mountain Pass and piped its wastewater to evaporation ponds. However, the pipeline ruptured and spilled radioactive materials that the mining operator had to clean up in the late 1990s. After the cleanup, Unocal was given a permit to operate for 30 years but sold the mine to Molycorp in 2008.

Molycorp also was fined for leaks and contamination. That company’s ownership ended in bankruptcy and the sale to MP Materials, the current owner. A long history of leaks and contaminated soil has unfortunately plagued the industry. That’s just the start. The mining industry around the world has also been a problem when it comes to the abuse of workers and their human rights.

With China mining most of the rare metals needed for the world’s electronics, the U.S. needs to get as much as possible through other means. Mining is not great for the environment, but it’s one option. The better option is through recovery through ITAD and electronics recycling.

This is where businesses and individuals come in. Keeping electronics out of the trash is essential. When items go to an electronics recycling facility, they’re evaluated to see if they have any value through either repairs and sales as refurbished items or if they’re good for parts for fixing other items. If they are not valuable for reuse, they’re broken down for recycling and reuse.

The United Nations reports that only 20% of the precious metals found within e-waste are recycled. Most companies feel it isn’t cost-effective. Research is ongoing to find inexpensive ways to recycle rare and precious metals without harming the environment. Chemical processes are often used to extract metals from electronic scrap. Electricity and the use of intense heat (flash joule heating) are effective for melting metals down, and then acid can be used to extract the rare metals through leaching. Newer technologies like the use of biomolecules to cling to the metals are also being tested.

Hydrometallurgy is one of the most common current recycling methods. The e-waste is crushed and then placed in an acid or alkaline solution. The metals are then separated through filtration, ion exchanges, and extraction. This method works best for copper, gold, silver, and zinc, however, so that’s why research is ongoing.

Other Benefits ITAD Offers

Recovering rare metals and other recyclable materials is a critical step toward protecting the environment for future generations. It’s also important to your business. As the first step in ITAD is to destroy data, you avoid costly government fines and potential lawsuits. If your items can be refurbished, the data is gone and cannot be recovered by someone looking to commit fraud. Data destruction stops bad actors in their tracks.

ITAD also helps you get some money back if your electronics still have value. If your IT assets could be fixed and resold, you get money back. That offsets the cost of ITAD services and the new equipment you’re purchasing. With benefits for both you and the environment, ITAD and electronics recycling is the best choice for disposing of old or broken equipment.

Carefully Choose an ITAD Provider

Make sure you do your homework. ITAD providers are not one-size-fits-all. The lowest rate may seem great when it comes to your financial picture, but do they cut corners to get to that low rate? Are they breaking down your IT assets and then sending them to another country where environmental protections are less strict? Paying more for electronic waste that’s processed within the U.S. following EPA regulations is well worth the added expense.

The best way to choose an ethical, responsible ITAD provider is by looking for e-Stewards and R2 certifications. Those are just two of several that are worthwhile, but it’s a good way to start finding an ITAD partner.