Jabil and Retronix Unite

By joining forces with Retronix, Jabil, a global electronic component manufacturer, will be able to salvage parts for reuse that would otherwise be shredded.

In March, Jabil, based in St. Petersburg, Fla., made the move to acquire Retronix, an established provider of re-balling services. Although details of the financial agreement were not revealed, a press release in November first publicized the purchase.

“Like Jabil, Retronix works with leading brands across industries such as telecommunications, defense, automotive, and healthcare,” the vice president of supply chain at Jabil, Jed Pecchioli, commented. “Now, these services will be available to Jabil customers, and together, we will strengthen the circular economy.”

In an interview with E-Scrap News, Pecchioli shared that Jabil’s acquisition is an early and significant stride into the fields of reuse and recycling. “There’s so much opportunity for everybody: customers, suppliers, the environment,” he stated.

“We are thrilled to welcome Retronix to the Jabil family,” Frank McKay, the chief procurement and supply chain officer at Jabil, added. “This acquisition demonstrates our commitment to our customers’ and our own environmental initiatives. As a trusted partner to many global brands, Jabil feels a strong sense of responsibility to not just support sustainability for ourselves, but to shepherd our customers towards decarbonization solutions like this — the reuse and recycling of electronic components.”

A Focus on Reuse

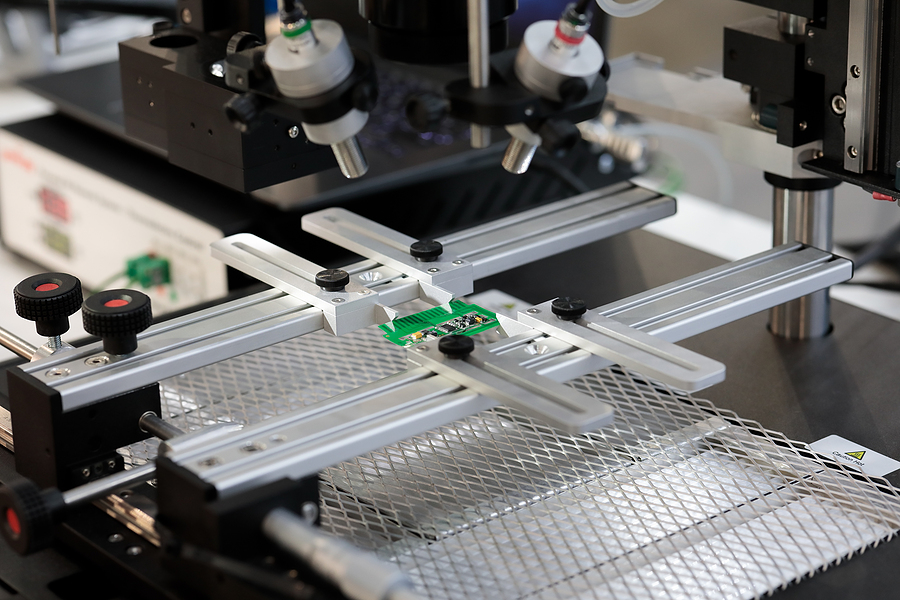

Since its formation 30 years ago, Retronix has been dedicated to the re-balling and re-tinning processes, specifically removing and replacing solder for components on printed circuit boards (PCBs). Facilities in both Austin, Texas and Glasgow, Scotland offer this service which is vital when lead versus tin balls are required due to environmental conditions. This necessity arises particularly within medical, military and aerospace applications, as Pecchioli pointed out.

Such detailed work also provides an opportunity to salvage parts from obsolete boards, giving them a chance to be reused or even resold.

Pecchioli conveyed that authenticity testing services are also provided by the company and that Jabil had originally partnered with Retronix for this purpose. He stated that currently, however, the firm’s focus is on creating a circular economy. “I think the part reclamation and the thing we can do with that in multiple avenues is a pretty cool and exciting thing we’re facing,” he stated.

The pandemic additionally created a larger demand for Retronix’s services as many of Jabil’s customers were unable to secure the parts needed for production, repair, or other services. At the same time, many of these customers had “boneyards” filled with reusable parts on bad PCBs that were not being used, and turned to Retronix to recover the reusable components from these stockpiles.

Reuse and value are two of the main goals for Retronix, as evidenced by its activity in recovering parts for resale. This process helps return money back to the customer, while also promoting a circular economy.

Retronix operations are in the process of being scaled up by Jabil, according to Pecchioli. And looking to the future, Jabil is putting efforts into instituting best practices that will serve each of Retronix’s core businesses.