Cascades Inc. Opens New Site

Cascades Inc., a company based in Kingsey Falls, Canada, has newly opened its Bear Island containerboard facility in Ashland, Virginia.

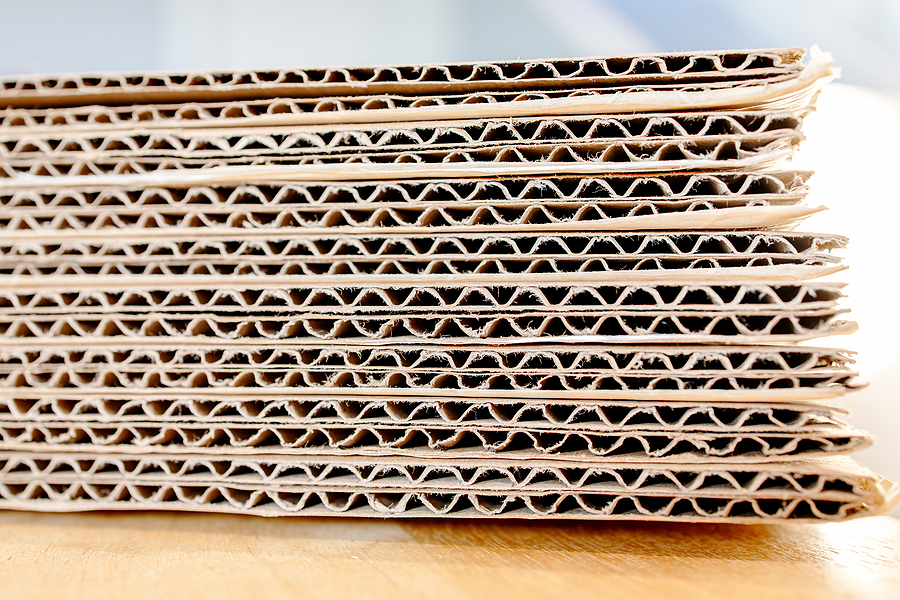

Boasting an impressive capacity of 465,000 tons per annum, the recently established mill promises to have a large impact on Cascades’ containerboard platform. This lightweight and fully-recycled material is expected to increase flexibility and expand the overall reach of Cascades Inc.

Also, it is estimated that the project produced over 700 jobs during construction, and 180 more in permanent employment when commercial production began.

“After the commissioning of the Greenpac mill nearly 10 years ago, the startup of Bear Island marks another historic milestone in the strategic modernization of our mill network,” Mario Plourde, Cascades’ CEO stated. “More than ever, Cascades has modern and competitive assets that will allow us to pursue long term growth in packaging, on a North American scale.”

Cascades Gains Mill from White Birch Paper

In 2018, Cascades acquired the mill from White Birch Paper, which had previously operated a newsprint paper machine. Though it was assumed that the Bear Island mill would be operational at the start of 2021, certain issues regarding obtaining labor and gaining material resources delayed its opening.

Adhering to the intentions of its strategic plan, Cascades has taken steps to invest in the modernization of its packaging and tissue core sectors, as well as expanding into other geographical regions. These pursuits are fundamental for the success of the organization’s objectives, according to Plourde.

He stated that, “In addition to the paper machine that is particularly well suited for conversion, the Bear Island site is strategically located for raw material sourcing and logistics. Based on the success of our Greenpac Mill [in Niagara Falls, New York], we expect this to be a highly competitive facility that will significantly contribute to the success of our containerboard operations by supporting our geographic expansion in the United States market, in addition to generating solid returns for our shareholders.”

Charles Malo, chief operating officer of Cascades Containerboard Packaging, also added, “The Bear Island site has several advantages including access to an experienced workforce with expertise in papermaking. Moreover, the site provides a platform for continued growth through downstream converting capacity. It will also allow us to better serve our customers and to expand our market share by increasing our capacity to provide clients with high quality recycled lightweight linerboard similar to what we produce at our Greenpac Mill.”

Bear Island Mill Quickly Moving Towards Full Capacity

The Bear Island mill will soon be running at full speed, as it is now entering the initial stages of ramping up production. During this process, the machine will slowly grow to its maximum capacity. Once everything is functioning optimally, an official celebration and inauguration event is planned for a later date.

Despite all of the global challenges concerning the supply chain, Cascades is immensely grateful to its partners and employees for making the second largest project in its history a success. As stated by Malo, this new mill will not only raise its market share but will also increase service quality with more sustainable solutions for customers.

Plourde also explained that, “This investment, one of the largest in our company’s history, is a decisive and very important strategic move in the modernization of our packaging assets.” Further stating, “By adding the Bear Island mill to our platform, more than 60 percent of our containerboard manufacturing capacity will be in the top quartile of the industry. In addition to offering a unique development platform, this plant will strengthen our geographic positioning and presence in the U.S. and will enhance the competitiveness of our asset base and our product offering regardless of economic conditions.”

He additionally highlighted that Bear Island will not just enhance operational efficiency but will also bring a dynamic product portfolio to the table. The plant will also support the production of 100-percent-recycled products with light basis weights. These items are highly sought after by customers, and provide an eco-friendly way of managing e-commerce needs.

Cascades Reports Facility Changes

Cascades has just disclosed that it will discontinue paper machine No. 2 at its Niagara Falls, New York plant, which has been inactive since November 2022. The sites machinery can produce 90,000 tons per annum; however, the organization believes it would need considerable investment to stay competitive.

The company reported that approximately 40 positions will be affected due to this machine’s permanent closure. Fortunately, these jobs are either vacant or can be replaced gradually to lessen any disruptions for employees.

Overall, Cascades Inc. excitedly awaits all of the benefits which are anticipated to arise from its newest Bear Island venture.