Carlsbad, California

Camston Wrather has unveiled plans to expand its operations significantly throughout America, following a period of little public exposure. The business specializes in a distinct methodology for harvesting metals from printed circuit boards.

Headquartered in Carlsbad, California, Camston Wrather is a leader in intermediate printed circuit board (PCB) processing. Through its system, three fractions are produced: one containing precious metals, another with other valuable metals, and the last consisting of polymers that can be recycled.

At a ribbon-cutting ceremony held in April, Dirk Wray, CEO of Camston Wrather, detailed the company’s novel technique. Unlike traditional methods which require high pressure, heat or acids to function, this technology is powered solely by water and does not depend on any other materials.

“We reuse everything and we have markets for everything,” he said. “We have no nasties here. That’s what really makes us very unique.”

The Company’s Launch

Beginning in 2014, Camston Wrather was the brainchild of both Mark Evans, who is now deceased, and Aaron Kamenash, who still works as the company’s chief innovation officer.

The founders started with a focus on chemistry, seeking to extract precious metals from mine tailings without using hazardous chemicals, like cyanide. Subsequently, they changed their R&D approach toward PCBs, leading to the successful development of intellectual property which has now become commercialized, as stated by Wray.

Camston Wrather’s Unique Name Origins

The creation of the name “Camston Wrather” was done with great care and precision, according to Wray. Ironically, no such person named “Camston Wrather” is related to the company.

As Wray explained, “Wrather” originates from a well-known early financial backer of Walt Disney, who was known to Evans when he was employed by the same firm. However, “Camston” is simply a fabricated name, chosen in order to create a business title which isn’t overly intricate.

A Proprietary System

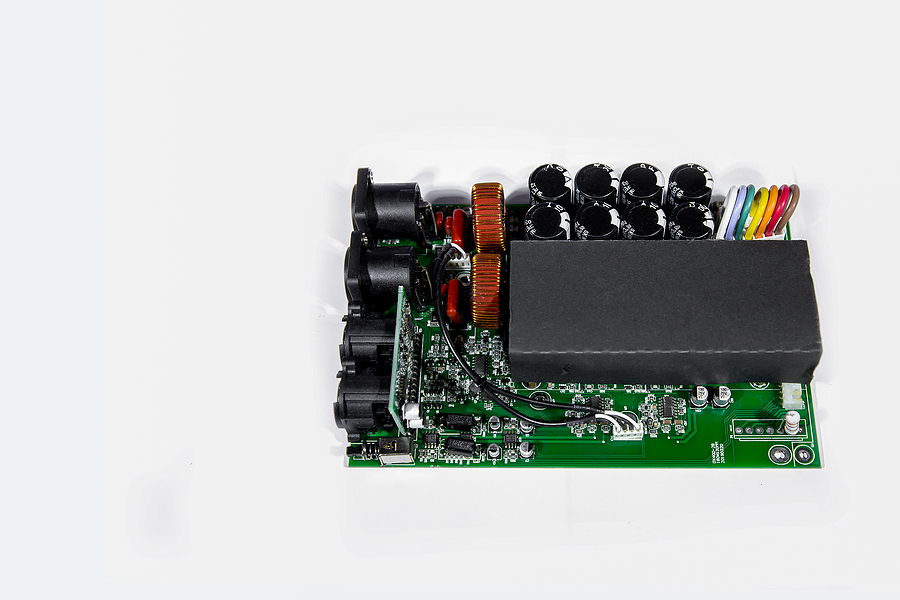

Carlsbad’s 115,000-square-foot facility uses an in-house developed technology for metals recovery. According to Wray, the shredding system at the facility employs a conventional front-end process consisting of size reduction, magnetic and optical sorting equipment.

Rather than shipping the shredded PCBs off to a smelter, Camston Wrather has developed its own distinctive process for metal liberation. As it stands, the firm’s procedure is protected via trade secrets. However, Camston Wrather is in the process of submitting patent applications to cover some of what is currently regarded as intellectual property.

Camston Wrather’s process yields two distinct metals outputs. One output is a concentrate containing gold, silver, and palladium, while the other includes an assorted mix of metals such as copper, nickel, tin, rare earths and more. The material, which has a sand-like texture, is then sent to refiners for further processing into pure metals. This approach works effectively on mid- and high-grade boards.

“Our concentrates are quite a bit more refined than a smelters are,” Wray stated.

Wray noted that the VERRA methodology used by the company can generate voluntary carbon credits and provide data to help comply with the demands of the U.S. Securities and Exchange Commission (SEC), which is expected to require auditors to certify greenhouse gas generation metrics.

7 Aggregation Locations

Camston Wrather boasts a network of seven aggregation sites located throughout the United States, with three based out of Florida, and one in Pennsylvania, Arizona, Missouri, and Texas. The company also owns a “green smelter” situated at the Carlsbad plant, which has been operational since the end of last year.

The organization spans an area of less than half a million square feet and employs 325 personnel.

ITAD Services Offered

Wray explained that several aggregation centers also offer ITAD services for customers. Camston Wrather made a notable move in 2019, acquiring its wholly owned ITAD and recycling subsidiary, Stream Recycling Solutions (SRS). The company now has locations within several cities, such as Tampa, Florida; Plant City, Florida; Fort Lauderdale, Florida; Carlsbad; St. Louis; and Phoenix.

To meet its downstream disposal needs, SRS has strategically joined forces with Texas Recovery Systems, a company which operates R2-certified locations in both the states of Texas and Pennsylvania, according to a CW company spokesperson.

Highlighting Camston Wrather’s comprehensive range of data services as well as its device resale business, Wray emphasized the importance of providing complete solutions for customers. “I think the future is to walk into a major company’s door and be able to provide a full service that’s transparent,” Wray said.

By 2023, Wray predicts that about 25 million pounds of material will be managed by the aggregation sites. It is estimated that this figure could even triple by 2024.

More than 20 million pounds of PCBs are processed by the Carlsbad site every year, with operations running 14 hours a day and five days a week, as mentioned by Wray. Next month there will be an official ribbon-cutting at the facility in Carlsbad to commemorate this event.

Wrather Partners with Schneider Electric

At the beginning of March, Schneider Electric, a Boston-based company, made a statement declaring its intention to supply its EcoStruxure Power and Process solutions and services to the Carlsbad plant. With this upgrade in place, it is expected to bring higher levels of efficiency as well as reduced energy consumption.

“The integrated solution provides greater visibility into their electrical system with power management, unified control, and the flexibility to easily scale, replicate and adjust as their operations grow,” according to a recent press release.

Midwest and East Coast Prospected For Further Expansion

As a result of rising demand from an influential Fortune 500 company, Camston Wrather is considering plans to install several new metal separation lines in various locations across the United States. Wray has indicated that the Midwest and East Coast regions are top considerations for potential plants.

In two years’ time, Camston Wrather is projected to have added at least two additional PCB processing lines. After three years, that number is expected to reach four total new lines of production.

“Circularity is really becoming a real thing in this industry, and we’re happy to be part of it,” Wray concluded.