Aqua Metals Inc.

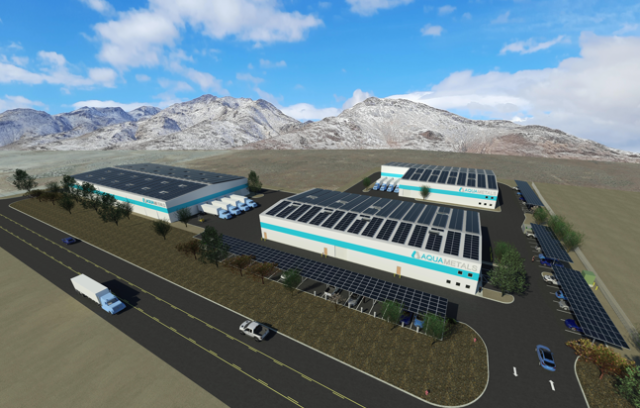

McCarran, Nevada-based company, Aquas Metals Inc., is preparing to initiate the phased construction of a 5-acre recycling campus in Tahoe-Reno, Nevada. The facility will be equipped with Li Aquarefining technology, allowing it to recycle up to 20 million pounds of lithium-ion battery (LIB) material annually.

Aqua Metals has noted that Nevada is the only state in the U.S. to have firms associated with every stage of LIB production including: mining, manufacturing, and recycling. As part of the anticipated plans, the company intends to build the recycling center at the Tahoe-Reno Industrial Center (TRIC). This area is experiencing rapid expansion within the battery recycling industry.

A Sustainable Campus Equipped with Unique Technology

Creating a location designed with sustainability as the focus is a core priority for Aqua Metals. The organization’s goal is to recycle enough lithium hydroxide, nickel, copper, and cobalt from used LIBs to provide the raw materials to manufacture 100,000 electric vehicle battery packs each year.

Aqua Metals has taken a major step to promote this aspiration by constructing what it believes to be the first lithium-ion battery recycling facility at its nearby Li AquaRefining pilot plant.

The company’s Li AquaRefining technology, a revolutionary patent pending system, offers a closed-loop recycling process that is based on electroplating. This method of metal refining eliminates the need for furnaces, and does not create much chemical waste. Electricity alone is used to produce metals of an exceptionally high purity.

The new commercial-scale campus will be powered with onsite renewable energy, with additional carbon-free energy being purchased in order to match usage and overall carbon impact.

Steve Cotton, president, and CEO of Aqua Metals explains, “Our campus vision is a testament to Aqua Metals’ commitment to the future of sustainable lithium battery recycling essential to meeting U.S. electrification and battery manufacturing ambitions in the coming decade”. “Our plans also represent a meaningful investment in clean energy jobs in the Nevada battery industry as a leader in the effort to create a secure and sustainable domestic supply chain for the metals needed to power electric vehicles and build battery energy storage systems.”

Phase One Plans

Aqua Metals recently revealed its definitive agreement to purchase the 5-acre area, along with an existing building located onsite. The completion of the acquisition is expected to take place in February. However, this is dependent on customary closing conditions as well as securing necessary funding for the purchase.

With a target of providing 3,000 tons of lithium-ion battery (LIB) black mass for recycling each year, plans are in motion to upgrade the existing onsite building and install a commercial-scale Li AquaRefining system.

After finishing redevelopment and equipment installation this year, operations at this new campus are expected to begin during Q1 of 2024.

Loan Details

Aqua Metals newly announced that it has taken the first steps to secure the purchase of the new property through a nondilutive loan. The company entered a nonbinding letter of intent with a mortgage lender that they have had prior experience with, and are in negotiations with another provider of debt financing for further development. This banker has also provided previous financing for Aqua Metals.

“We believe our phased campus will enable us to scale cost-effectively as we acquire new customers and build new partnerships,” Cotton states. “We expect that phase one will process 3,000 metric tons of black mass per year at full capacity–30 times that of our current pilot operation–resulting in significant revenue for the company.”

Phase Two

Phase two of the ambitious project involves building a second LIB recycling facility at the same site, which will be capable of processing an extra 6,000 tons of lithium black mass every year. Plus, extra space for research and development into sustainable recycling innovations, as well as new LIB chemistries is expected to be constructed. This will help expand the scope of the company’s clean metals recycling campus.

Aqua Metals’ chief engineering and operating officer, Ben Taecker, says “With our new campus, we are taking what we’ve already learned from building and operating our successful Li AquaRefining pilot facility and scaling it at the right pace”. “With on-site clean energy and our ground-breaking Lithium AquaRefining technology, we believe this will be the cleanest and safest lithium battery recycling facility in the world.”